Toroidal Core Current transformers

EPRO Gallspach GmbH offers to its customers a bright variety of toroidal core current transformers. All devices are calculated according to customers specifications.

What is a toroidal current transformer?

A toroidal current transformer or "measuring transformer" is a component of a power or distribution transformer and is used to convert a large current, what is difficult to measure on the primary side, into a small current, what is easier to measure on the secondary side.

Which types of toroidal core current transformers EPRO offers?

EPRO produces toroidal core current transformers for metering and protection. All devices are designed and produced according to customers specifications. Pease find more information about the offered types at the bottom of this side.

Toroidal transformers for measuring:

Measuring transformers are, according to their physical principle, transformers. They convert the high current or voltage on their primary side proportionally and in phase into a smaller current or voltage (ratio), which then can be processed in devices such as measuring instruments, electricity meters and protective relays.

Measuring core is the designation for a wound core of a current transformer, which is preferably used for measurement and invoicing. This is referred to as accuracy classes 0.1 to 0.5 or 1 to 5 in the IEC or 0.3 to 1.2 in the ANSI standard.

Toroidal core current transformers for protection purposes:

Protective core is the designation for a wound core of a current transformer, which is preferably intended for the protection of the system in short-circuit currents.

They are used to transmit the reduced current to protection relays, control devices or regulating devices even at very high overcurrent (e.g. 20 times the rated current).

What do the different accuracy classes mean?

The accuracy class indicates a current or voltage transformer whose current or phase error remains within specified limits under prescribed conditions of use.

There are two types of accuracy classes:

- Measurement classes characterize transformers for exact measurement and invoicing of quantities in the design area.

- Protection classes characterize transformers for detecting fault conditions in the network.

For medium-voltage transformers, depending on the Standard, the following accuracy classes are valid:

IEC and all similar standards:

CURRENT TRANSFORMER:

Measurement classes: 0.1; 0,2; 0,5; 1; 3; 5; 0.2S; 0.5S

Protection classes: 5P; 10P; TPX

Protection classes with knee point voltage: PX; TPS

Protection classes with linear cores: 5PR, 10PR; TPY; TPZ

VOLTAGE TRANSFORMER:

Measurement classes: 0.1; 0,2; 0,5; 1; 3

Protection classes: 3P; 6P

IEEE and all similar standards

CURRENT TRANSFORMER:

Measurement classes: 0.15; 0.15S; 0.3; 0.6; 1.2

Protection classes: C, T, X

VOLTAGE TRANSFORMER:

Measurement classes: 0.15; 0.3; 0.6; 1.2

What are air gap cores for, what special properties do they have in comparison?

In order to achieve high accuracy limit factors of current transformers, magnetic cores are linearized by introducing a defined air gap.

In addition to the ampere-turns in the iron, this causes a significantly higher and induction-proportional ampere-turns into air, which linearizes the magnetization curve and reduces the remanence.

In contrast, the magnetization current increases significantly.

Air gap cores are used in the accuracy classes PR, TPY and TPZ.

Production 100% in Austria:

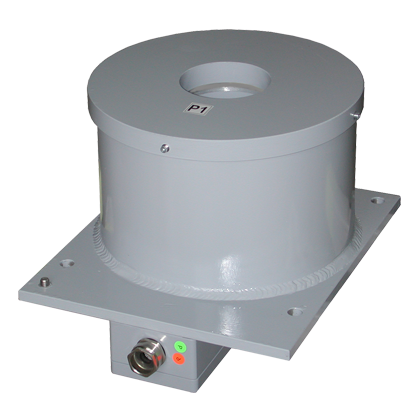

Production of the toroidal core current transformers is done 100% in our headquarters in Gallspach / Austria, from core winding to the tested end product the whole process underlies our rigid quality control. Electrical tests are fulfilled directly in our own state of the art current transformer laboratory.

Security and reliability:

These products are designed for the use on the power transformer bushing, the use of proven and certified materials able to withstand oil under high temperature, kerosine steam in the transformer drying process and more mechanical or chemical stresses is important for maximum lifetime and reliability. EPRO takes care to use only proven and certified materials for maximum security. The EPRO ring core CT ´s are accredited according to PTB and BEV.